Complete Guide to Nuts: Hex, Nyloc, Wing, Lock & More

Complete Guide to Nuts: Hex, Nyloc, Wing, Lock & More

Nuts are essential threaded fasteners that pair with bolts and screws to create secure mechanical joints. With dozens of specialized types available, selecting the right nut ensures proper clamping force, vibration resistance, and long-term reliability in your assembly.

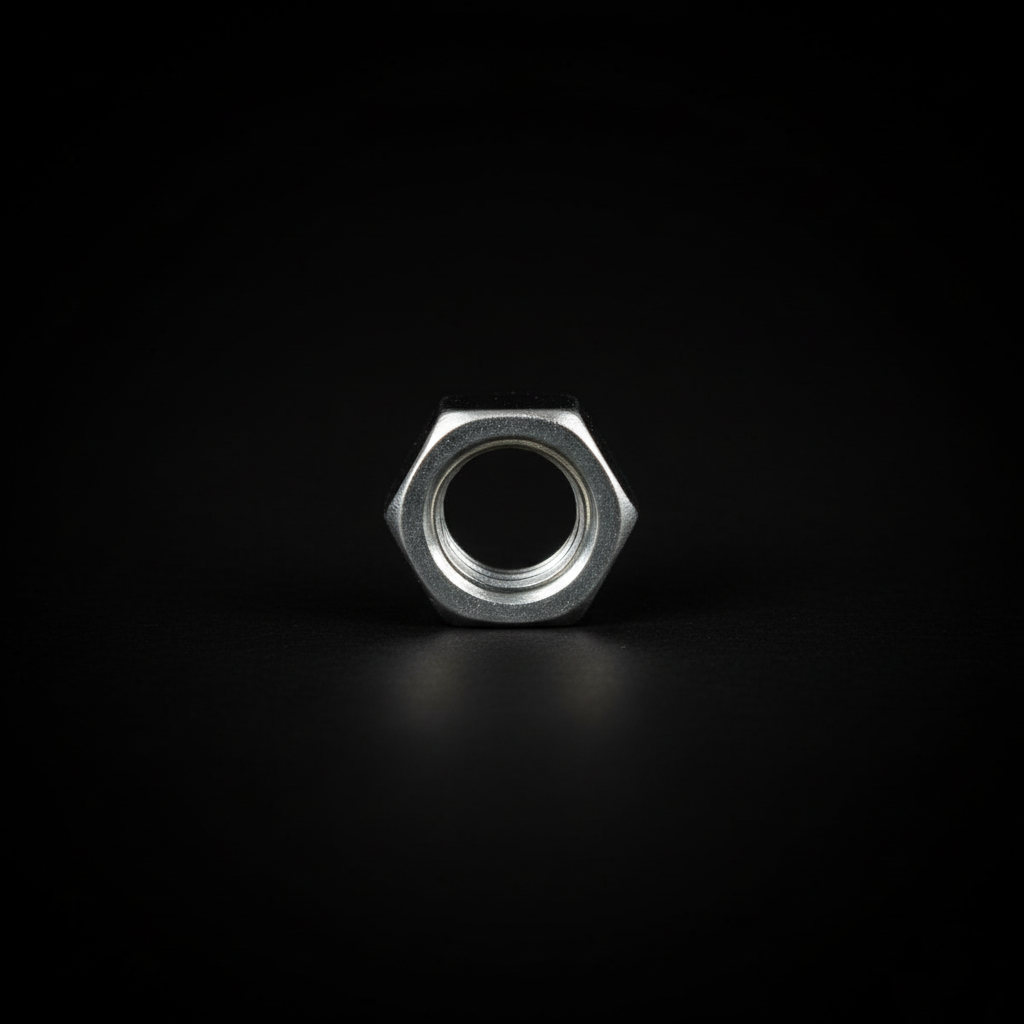

1. Hex Nut, Square Nut, and Flange Nut

Hex nuts are the most common industrial nuts, featuring six sides for wrench tightening. Square nuts have four sides and flange nuts include an integrated washer surface for load distribution. Available materials include zinc-plated mild steel, stainless steel (SS304), brass, and nylon for insulation. These nuts are essential for pairing with bolts and screws in machinery, construction, automotive, and general assembly applications.

Shop Hex Nuts →

Shop Hex Nuts →

2. Lock Nuts: Nyloc, Flange Nyloc, and Metal Lock Nut

Nyloc nuts use a nylon insert to prevent loosening under vibration, making them essential for automotive suspensions, machinery, and vibration-prone assemblies. Flange nyloc nuts combine a flange with the nylon insert for better load distribution and vibration resistance. Metal lock nuts provide all-metal prevailing torque for high-temperature use where nylon inserts would fail. These self-locking nuts eliminate the need for separate lock washers in many applications.

Browse Lock Nuts →

Browse Lock Nuts →

3. Wing Nut, Dome Nut, and Barrel Nut

Wing nuts allow tool-free tightening using hand wings, perfect for frequently adjusted or removed components. Dome (cap) nuts protect exposed threads and provide a finished appearance for visible fastening applications. Barrel (cross dowel) nuts are used in furniture assemblies for hidden fastening, working with bolts to create strong joints in particleboard, MDF, and solid wood.

4. Insert Nuts: LF, RF, D-Type, and Tee Nuts

Insert nuts (LF/RF/D-type) and tee nuts provide robust threaded points in wood, plastic, and soft materials. They are commonly used in furniture, panels, and injection-molded parts, allowing bolts and machine screws to be repeatedly installed and removed without damaging the base material. LF (left flange) and RF (right flange) refer to the orientation of the barbs or prongs that grip the material.

Shop Insert Nuts →

Shop Insert Nuts →

5. Specialty Nuts: Cage, Clinch, Rivet, Weld, and Keps

Cage nuts, clinch nuts, rivet nuts (rivnuts), weld nuts, and keps nuts serve specialized mounting needs in server racks, sheet metal, and welded assemblies. Cage nuts snap into square holes in rack rails for easy server mounting. Clinch nuts and rivet nuts create permanent threads in thin sheet metal. Weld nuts are spot-welded to panels. Keps nuts have an integrated lock washer for vibration resistance.

Explore Specialty Nuts →

Explore Specialty Nuts →

6. Long Nuts and Profile Nuts

Long (coupling) nuts join threaded rods or extend bolts; profile nuts fit into extruded T-slot profiles for adjustable machine framing. Both are used in structural and modular assemblies, offering flexibility in construction and easy reconfiguration.

View All Nuts →

View All Nuts →

Complete Nut Solutions for Every Application

From standard hex nuts to specialized clinch nuts and profile nuts, ScrewBazar provides the complete range of nuts for all industries and applications. Our technical team assists with thread matching, material selection, and locking mechanism recommendations. Contact us for bulk pricing and same-day dispatch.