Complete Guide to Washers: Plain, Spring, Lock & Specialty Types

Complete Guide to Washers: Plain, Spring, Lock & Specialty Types

Washers are critical components that distribute load, prevent surface damage, provide spacing, and prevent fastener loosening. Understanding different washer types and their applications ensures optimal joint performance and longevity.

1. Plain Washers, Fibre Washers, and Nylon Plain Washers

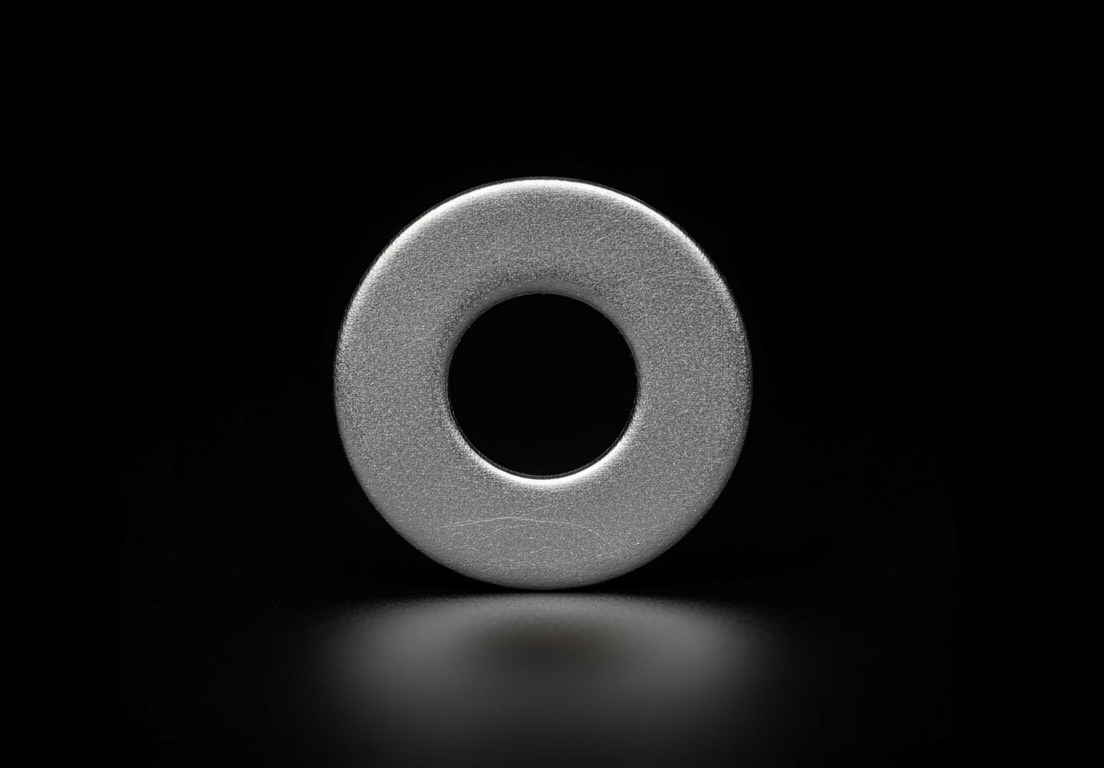

Plain washers (flat washers) are the most common type, distributing fastener load over a larger area to prevent surface damage and pull-through in soft materials. Standard sizes follow bolt sizing (M3 washer for M3 bolt) with inner diameter slightly larger than bolt diameter and outer diameter typically 2-3x inner diameter. Fibre washers are made from compressed cellulose or synthetic fibers, providing electrical insulation, vibration damping, and sealing in low-pressure applications. Nylon plain washers (nylon round washers) are lightweight, non-conductive, corrosion-proof alternatives used in electronics to prevent electrical shorts, chemical equipment for corrosion resistance, and applications requiring non-marring, non-scratching properties.

Shop Plain Washers →

Shop Plain Washers →

2. Spring Washers, Wave Washers, and Conical Disc Washers

Spring washers (split lock washers) have a split ring with ends offset vertically, creating spring tension when compressed. This tension maintains preload and provides anti-vibration locking by digging into mating surfaces. Widely used in machinery, automotive, appliances, and anywhere vibration could cause loosening. Wave washers have wave-like undulations providing axial spring force in smaller space than coil springs. Used for taking up tolerance stack-up, applying consistent pressure in assemblies, and providing controlled friction in mechanisms. Conical disc washers (Belleville washers) are cone-shaped spring washers providing high spring rates and load capacity in small axial space.

Browse Lock Washers →

Browse Lock Washers →

3. Tooth Lock Washers: External Tooth, Internal Tooth, and Star Washers

External tooth washers (Ext-Tooth Washer) have teeth projecting outward from outer edge, biting into both fastener head/nut and component surface to prevent rotation. Internal tooth washers (Int-Tooth Washer) have teeth projecting inward from inner edge toward center hole, concentrating locking force under fastener head for maximum anti-rotation effectiveness in confined spaces. External star washers (Ext-Star Washer) and internal star washers (Int-Star Washer) have multiple pointed teeth arranged in star pattern, providing superior locking through increased bite points.

Shop Star Washers →

Shop Star Washers →

4. Wedge-Lock Washers and Taper Washers

Wedge-lock washers (Nord-Lock type) consist of a pair of washers with cammed surfaces facing each other and radial teeth on opposite sides. When bolt is tightened, teeth grip mating surfaces while cammed surfaces create wedge effect that prevents rotation. If bolt attempts to loosen, cam angle is designed to be greater than thread pitch angle, physically preventing movement. This makes wedge-lock washers the most effective anti-vibration locking system, suitable for critical joints in heavy machinery, wind turbines, railway applications, mining equipment, and structural steel where loosening could be catastrophic. Reusable and effective even in extreme vibration environments. Taper washers are angled washers used with I-beams and channels where structural members meet at angles. They compensate for slope of beam flanges, ensuring bolt sits perpendicular to load direction. Available in standard slopes (typically 5°, 8°, 14°) matching structural steel specifications. Essential in steel construction, bridge building, and structural connections where proper bolt alignment on angled surfaces is required.

5. Circlips: Type A, Type B, and Type E

Circlips (retaining rings, snap rings) are split rings that fit into grooves on shafts or inside bores to retain components. Circlip Type A (external circlip for shafts) fits into groove on outside of shaft, preventing axial movement of components like bearings, gears, or pulleys. Circlip Type B (internal circlip for bores) fits into groove inside a bore or housing, retaining components from outside. Circlip Type E (E-clip, C-clip) is a simple C-shaped clip that pushes onto shaft without requiring groove, though providing less retention force than grooved types. All circlips are made from spring steel and install/remove using special circlip pliers with tips that fit into holes in ring ends. Essential in automotive transmissions (gear retention), electric motors (bearing retention), hydraulic cylinders (piston retention), and any assembly where components must be retained on shafts or in bores without threading. Circlips allow easy disassembly for maintenance while providing reliable retention during operation. Sizes range from 3mm shaft diameter to 300mm+ for industrial applications.

Complete Washer Solutions

From basic plain washers to advanced wedge-lock systems and precision circlips, ScrewBazar supplies all washer types for proper load distribution and locking. Our team helps select appropriate washer types for your specific vibration, load, and environmental conditions. Contact us for technical guidance and bulk supply.