Phillips Machine Screws Explained: Pan, CSK, Truss & WW Variants

Phillips Machine Screws Explained: Complete Guide to Cross-Head Fasteners

Phillips machine screws are the workhorse of modern manufacturing, combining reliable torque transfer with widespread tool availability. The cross-head (Phillips) drive design enables self-centering, consistent installation, and controlled cam-out to prevent over-tightening. This comprehensive guide explores every Phillips machine screw variant—Pan Head, CSK (Countersunk), Truss Head, and WW Pan—available at ScrewBazar.

1. Phillips Drive Technology and Advantages

Phillips machine screws feature the iconic cross-head recess designed in the 1930s to enable power tool driving in assembly lines. The cruciform shape provides four driving surfaces with tapered walls that create self-centering action when screwdriver engages—the tool automatically centers itself in the recess for quick, reliable driving. The tapered design also enables controlled cam-out: when torque exceeds design limits, the driver lifts out of recess rather than stripping threads or breaking screws. This protects assemblies from overtightening damage while providing consistent clamp loads in high-speed production. Phillips screws are manufactured following ISO 7045, ISO 7046, and DIN 965/DIN 966 standards ensuring interchangeability and consistent performance. Drive sizes are designated by numbers: PH0 (M1.6-M2.5), PH1 (M3-M4.5), PH2 (M5-M6), PH3 (M8+)—matching driver size to screw size is critical for optimal torque transfer. Materials include zinc-plated mild steel (general indoor use), stainless steel SS304 (outdoor/corrosion resistance), SS316 (marine/chemical environments), brass (electrical/decorative), and nylon (electrical insulation). Phillips machine screws are essential in electronics manufacturing, appliance assembly, HVAC installation, automotive interiors, furniture production, and general machinery assembly. The widespread availability of Phillips drivers (manual and power) makes these screws ideal for field service and repair applications. At ScrewBazar, we stock Phillips machine screws from M2 to M12 in lengths from 4mm to 100mm.

Shop Phillips Screws →

Shop Phillips Screws →

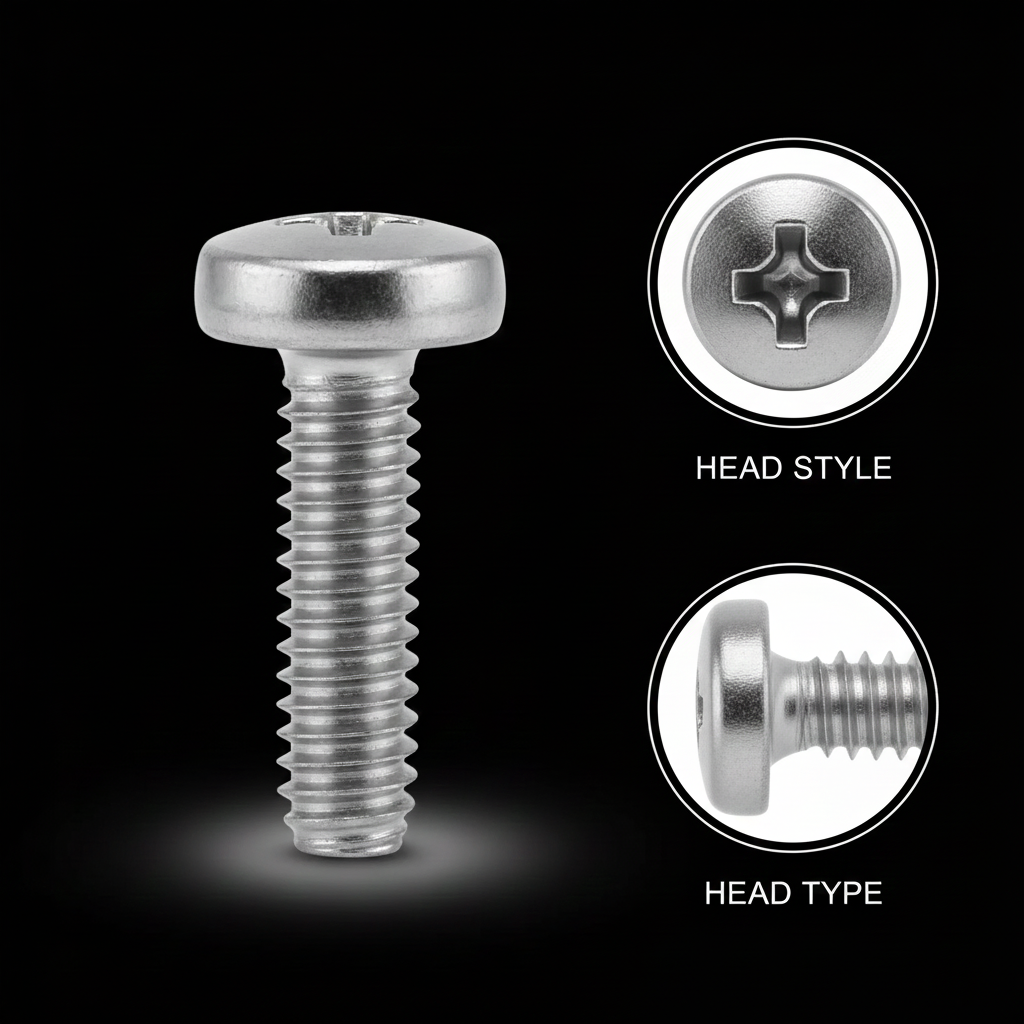

2. Pan Head Phillips - Universal Fastening Solution

Pan head Phillips screws feature a rounded, low-profile head with flat bearing surface providing excellent load distribution while maintaining relatively compact height. The pan head (also called round head) offers the optimal balance of head strength, bearing area, and clearance—making it the most versatile and widely used machine screw head style. Pan head height is typically 0.5-0.6x diameter, providing substantial bearing surface without excessive protrusion. The rounded top contour reduces snag hazards and provides aesthetic appeal in visible applications. Pan head Phillips screws are the default choice for electronics assembly (PCB mounting, chassis assembly), appliance manufacturing (control panels, internal brackets), HVAC equipment (ductwork, unit assembly), electrical panels (breaker mounting, busbar connections), automotive assembly (interior trim, under-hood components), furniture (hidden connections, bracket mounting), and general machinery (guard panels, covers, brackets). The pan head works equally well with metal, plastic, and composite materials. Installation with power drivers is straightforward—the self-centering Phillips recess guides bit engagement even at high speeds. Optimal torque ranges: M3=0.8-1.0 Nm, M4=1.5-2.0 Nm, M5=2.5-3.5 Nm (zinc-plated steel). Materials include carbon steel zinc-plated for corrosion resistance, stainless steel SS304 for food/medical/outdoor use, and black oxide for aesthetic finish. Pan head Phillips often pair with plain washers or lock washers depending on application requirements—washers increase bearing area and provide vibration resistance. Common sizes at ScrewBazar include M3, M4, M5, M6 in various lengths, with bulk packaging for high-volume manufacturing.

Browse Pan Head Phillips →

Browse Pan Head Phillips →

3. CSK Head Phillips - Flush-Mount Precision

CSK (Countersunk) Phillips screws feature a flat-top, conical head designed to sit flush with or below the material surface when installed in countersunk holes. The head angle (typically 82° or 90° included angle) matches standard countersink tools, ensuring proper seating and load distribution. The flat top creates perfectly smooth surfaces without protruding fasteners—essential for sliding mechanisms, aerodynamic surfaces, decorative finishes, and safety applications where snagging must be prevented. CSK Phillips screws are extensively used in door hardware (hinges, strike plates requiring flush mounting), furniture (drawer slides, cabinet fronts), automotive body panels (exterior trim, door skins), aircraft interiors (panel mounting, seat tracks), machine guards (smooth surfaces for safety), and decorative applications (visible fastening with clean appearance). The Phillips drive in countersunk screws provides better driving access than slotted alternatives when screw is recessed below surface—the cruciform recess maintains tool engagement even at depth. Installation requires proper countersinking: hole angle must match head angle, and depth should position screw head flush or 0.1-0.3mm below surface. Improper countersinking reduces clamp load and can cause head splitting. Countersink tools should be sharp and operated at correct speed (too fast burns material, too slow tears edges). Materials include zinc-plated steel, stainless steel SS304 (outdoor/marine applications), and brass (decorative/electrical applications). When installing CSK screws in soft materials (wood, plastic, soft metals), use countersunk washers to distribute load and prevent pull-through. Torque control is critical—overtightening draws head below surface reducing bearing area; undertightening leaves head proud. Sizes from M3 to M8 available at ScrewBazar with various head angle options.

Shop CSK Phillips →

Shop CSK Phillips →

4. Truss Head Phillips - Maximum Bearing Surface

Truss head Phillips screws (also called mushroom head or oval head) feature an extra-wide, low-profile head providing maximum bearing surface in minimum height. The head diameter is typically 1.5-2x larger than pan head while maintaining similar or lower profile height. This large bearing surface makes truss head screws ideal for thin sheet metal, soft plastics, composite materials, and applications prone to vibration where pull-through is a concern. The wide head distributes clamping force over larger area, reducing stress concentration and preventing material distortion or damage. Truss head Phillips screws are essential in sheet metal assembly (HVAC ductwork, electrical enclosures), automotive trim (interior panels, headliners), appliance manufacturing (thin steel panels, plastic components), electronics (laptop cases, tablet frames), trailer manufacturing (aluminum skin, thin panels), and sign fabrication (mounting panels without visible distortion). The low profile minimizes snag hazards while the large head provides excellent grip for disassembly even after extended service. The Phillips drive enables efficient power tool installation—the self-centering recess maintains alignment even when driving into pre-threaded holes or thin materials that may flex. Installation torque should be monitored to prevent overtightening—the large bearing area can mask excessive torque until material deformation occurs. Materials include zinc-plated steel for general use, stainless steel SS304 for outdoor exposure, and special coatings for aluminum-compatible applications (preventing galvanic corrosion). Truss head screws often eliminate need for separate washers in thin-material applications, reducing assembly steps and costs. Common sizes include M4, M5, M6 with lengths from 6mm to 40mm. When specifying truss head screws, verify head diameter will fit within available clearance—the oversized head may interfere with adjacent components. ScrewBazar supplies truss head Phillips screws with complete dimensional specifications and application guidance.

Explore Truss Head →

Explore Truss Head →

5. WW Pan Phillips - Wide Washer Integrated Design

WW Pan Phillips screws (Wide Washer Pan) combine standard pan head with an integrated wide flange, creating a hybrid design that functions like a screw with built-in washer. The wide flange increases bearing diameter by 50-100% compared to standard pan head while maintaining the familiar rounded profile. This design provides superior load distribution in thin materials, eliminates need for separate washers (reducing part count and assembly time), and improves vibration resistance through increased friction area. The integrated washer cannot be lost or installed incorrectly—a significant advantage in high-volume production and field assembly. WW Pan Phillips screws are widely used in automotive manufacturing (body panel attachment, trim mounting), HVAC installation (thin ductwork, panel connections), electronics manufacturing (thin chassis, cover plates), appliance assembly (thin steel and plastic panels), sheet metal fabrication (general assembly of thin gauge materials), and construction (metal roofing accessories, siding attachment). The Phillips drive provides reliable power tool operation with self-centering for rapid installation. The wide washer head is particularly effective in vibration-prone applications—the increased contact area creates friction that resists loosening more effectively than standard heads. Materials include carbon steel with various platings (zinc, zinc-nickel, geomet), stainless steel SS304 for corrosion resistance, and aluminum-compatible coatings. Installation considerations: verify head diameter won't interfere with adjacent components; the wide flange requires more clearance than standard pan head. Torque specifications are similar to standard pan head but monitor for material deformation—the large bearing area can embed into soft materials if overtightened. Sizes from M4 to M8 with lengths from 8mm to 50mm available at ScrewBazar. The WW Pan design represents optimal engineering for thin-material fastening applications.

Complete Phillips Machine Screw Solutions

From versatile Pan Head to specialized WW Pan configurations, ScrewBazar provides the complete range of Phillips machine screws for every application. Our technical team assists with head style selection, material specification, and installation guidelines. Contact us for detailed dimensional data, torque recommendations, bulk pricing, and same-day dispatch to your facility.