Torx Machine Screws Technical Guide: Standard & Security Variants

Torx Machine Screws Technical Guide: Superior Performance Through Star Drive Technology

Torx screws represent the evolution of fastener drive technology, offering superior torque transfer, virtually eliminated cam-out, and extended tool life compared to Phillips or slotted alternatives. The 6-point star drive design provides multiple contact surfaces for consistent, high-torque fastening. This technical guide covers Pan Torx, CSK Torx, Security Pan Torx, and Security CSK Torx screws with engineering insights for optimal application.

1. Torx Drive Technology and Engineering Advantages

Torx screws feature a 6-pointed star-shaped recess (hexalobular internal drive) developed to overcome limitations of Phillips and hex socket designs. The star geometry creates six driving surfaces with radial contact faces perpendicular to rotational force—this eliminates the wedging action that causes cam-out in Phillips drives. Torx enables 10-15 times higher torque transfer before cam-out compared to equivalent Phillips screws, allowing higher clamp loads with smaller fasteners. The increased contact area distributes driving forces evenly, significantly extending bit life—a critical advantage in high-volume manufacturing where tool wear costs are substantial. Torx sizes are designated by T-numbers: T5, T6, T8, T10, T15, T20, T25, T27, T30 (most common in machine screws M3-M8), with each size corresponding to specific screw diameters. The self-centering star recess guides bit engagement quickly and maintains alignment even under high torque—reducing installation time and preventing fastener damage. Torx technology is standardized under ISO 10664, ensuring consistent dimensions and performance globally. Materials for Torx machine screws include hardened carbon steel (grades 8.8, 10.9, 12.9), stainless steel SS304/SS316 (corrosion resistance), and specialized coatings (black oxide, zinc-nickel, geomet). Applications span automotive manufacturing (engine assembly, chassis components), computer/server assembly (rack mounting, internal components), industrial machinery (high-torque connections), consumer electronics (tablets, smartphones, laptops), and security applications (tamper-resistant fastening). ScrewBazar stocks Torx machine screws from M3 to M10 in various head configurations with matching driver bits and installation guidance.

Shop Torx Screws →

Shop Torx Screws →

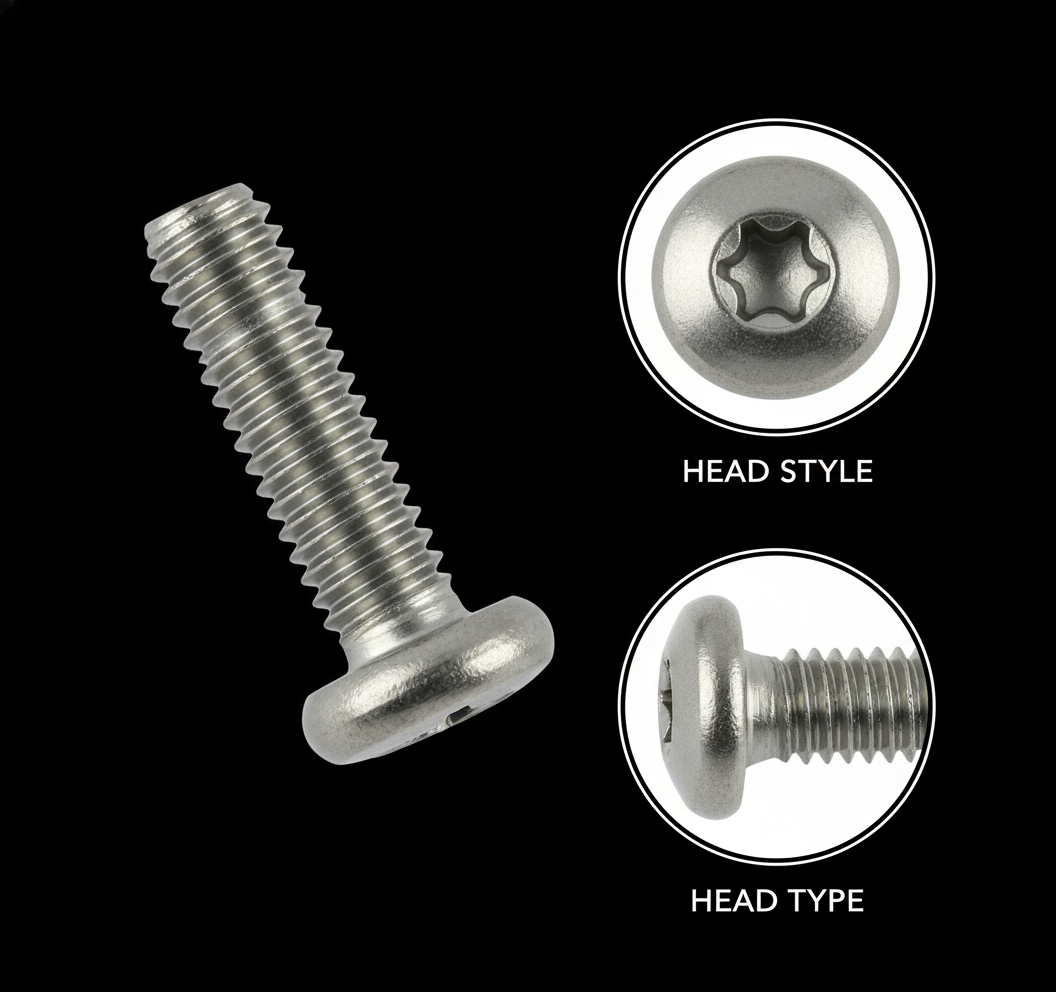

2. Pan Torx - High-Torque General Purpose Fastening

Pan Torx screws combine the low-profile pan head with superior Torx drive technology, creating versatile fasteners suitable for applications requiring higher torque than Phillips equivalents. The rounded pan head provides good bearing surface with minimal protrusion (typical height 0.5-0.6x diameter), while the Torx recess enables controlled high-torque installation without driver slippage. Pan Torx screws are increasingly popular in automotive assembly (replacing Phillips in higher-torque applications), electronics manufacturing (server racks, network equipment), machinery assembly (motor mounts, pump housings), appliance manufacturing (compressor mounting, high-stress connections), and construction equipment (panel mounting, structural brackets). The ability to achieve higher clamp loads allows using smaller diameter screws for equivalent holding power—reducing weight and cost in high-performance applications. Installation with power tools is faster than Phillips due to eliminated cam-out—operators can apply full torque in single engagement without bit walking or stripping. Recommended installation torque for Pan Torx (Grade 8.8): M3=1.0 Nm, M4=2.0 Nm, M5=3.5 Nm, M6=6.0 Nm, M8=14.0 Nm (approximately 25% higher than Phillips equivalents). Materials include carbon steel zinc-plated (general industrial), stainless steel SS304 (outdoor/food grade), and black oxide (aesthetic/mild corrosion protection). Pan Torx screws often pair with lock washers or nyloc nuts in vibration environments. The star recess maintains engagement even when contaminated with oil, grease, or debris—an advantage over Phillips in automotive and machinery applications. Common sizes M4, M5, M6 available at ScrewBazar with bulk pricing for OEM manufacturing.

Browse Pan Torx →

Browse Pan Torx →

3. CSK Torx - Flush Mounting with Maximum Torque Control

CSK Torx screws feature countersunk heads (82° or 90° included angle) with Torx drive, combining flush-mounting aesthetics with superior torque capacity. The conical head sits flush with material surface when properly countersunk, creating smooth finishes without protruding fasteners. Unlike CSK Phillips or slotted screws which are prone to cam-out or bit slippage when recessed, CSK Torx maintains reliable drive engagement even when installed below surface—critical for applications requiring precise torque control in flush-mounted connections. CSK Torx screws excel in automotive body panels (exterior trim, aerodynamic components), aircraft interiors (seat tracks, panel mounting), machinery guards (smooth surfaces for safety), decorative applications (architectural fixtures, furniture), and anywhere flush mounting with high torque is required. The Torx drive enables consistent installation torque regardless of access angle or operator variation—improving assembly quality and reducing fastener-related defects. Installation requires proper countersinking matching head angle, with depth positioning head 0-0.2mm below surface. The high torque capacity of Torx is particularly valuable in countersunk applications where angled bearing surface reduces mechanical advantage—Torx compensates by enabling higher driver torque input. Materials include carbon steel with protective coatings, stainless steel SS304 for marine/outdoor applications, and specialty finishes for aluminum compatibility. When installing CSK Torx in thin materials, monitor torque carefully—high drive capability can overtighten and pull through soft substrates. Use countersunk washers in plastics and composites for load distribution. Sizes M3 to M8 available at ScrewBazar with precise dimensional specifications for countersink depth calculation.

Shop CSK Torx →

Shop CSK Torx →

4. Security Pan Torx - Tamper-Resistant Fastening

Security Pan Torx screws feature modified Torx recess with central post (pin in center), requiring specialized security Torx drivers for installation and removal. Standard Torx drivers cannot engage the recess due to central post interference—providing tamper resistance against casual removal. This security feature is essential in public access areas, consumer products requiring controlled servicing, valuable equipment protection, and applications where unauthorized disassembly poses safety or warranty concerns. Security Pan Torx screws are widely used in elevators and escalators (panel access control), ATMs and payment terminals (preventing unauthorized access), public restrooms (fixture protection), consumer electronics (warranty seals, authorized service only), playground equipment (preventing vandalism), and transportation (bus/train interior fixtures). The pan head profile maintains low-profile appearance while providing good bearing surface. Installation and removal require security Torx bits with hollow center accommodating the pin—these tools are available but not commonly carried, providing effective deterrent against casual tampering while allowing authorized service. The underlying Torx geometry maintains all performance advantages: high torque capacity, no cam-out, extended tool life. Security level is "tamper-resistant" not "tamper-proof"—determined adversaries can remove these screws, but casual interference is effectively prevented. Materials include hardened carbon steel (drilling resistance), stainless steel SS304 (outdoor/marine), and specialty coatings. Installation torque matches standard Torx specifications. Common applications use M4, M5, M6 sizes available at ScrewBazar with matching security bits.

Explore Security Torx →

Explore Security Torx →

5. Security CSK Torx - Flush Tamper-Resistant Fastening

Security CSK Torx screws combine countersunk flush-mounting with tamper-resistant security features, providing both aesthetic clean lines and controlled access protection. The countersunk head sits flush with surface while the pin-in-center Torx recess requires specialized security drivers, making these screws ideal for visible security applications where both appearance and tamper-resistance matter. Security CSK Torx screws are essential in public facility fixtures (washroom accessories, door hardware), access control panels (card readers, keypad housings), vending machines (access panels, coin mechanisms), retail displays (high-value product fixtures), transit vehicle interiors (flush-mounted panels, seat fixtures), and medical equipment (patient access restrictions). The flush mounting prevents snagging and provides professional appearance while security feature controls disassembly. Installation requires countersinking for flush seating plus security Torx driver with hollow center. The combination makes unauthorized removal significantly more difficult—the screw cannot be extracted with standard tools, and even if security driver is obtained, flush mounting complicates engagement. Materials are selected for tamper resistance: hardened steel resists drilling, stainless steel SS304 prevents corrosion-induced weakening, and special coatings add lubricity (preventing galling during installation). Installation torque follows CSK Torx specifications with careful monitoring to position head precisely flush—security applications demand consistent quality. Security CSK Torx represents premium tamper-resistant fastening where both security and aesthetics are critical. Sizes M4, M5, M6 available at ScrewBazar with matching security drivers and installation training available for large-scale projects.

Advanced Torx Screw Solutions

From standard Pan Torx for high-torque applications to Security CSK Torx for tamper-resistant installations, ScrewBazar provides complete Torx screw solutions with technical expertise. Our team assists with Torx size selection, security level specification, and driver tool sourcing. Contact us for engineering data, installation specifications, bulk pricing, and authorized service tool programs.