Allen Screws Deep Dive: SHCS, BHCS, CSK & Specialized Types

Allen Screws Deep Dive: Complete Technical Guide to Socket Head Cap Screws

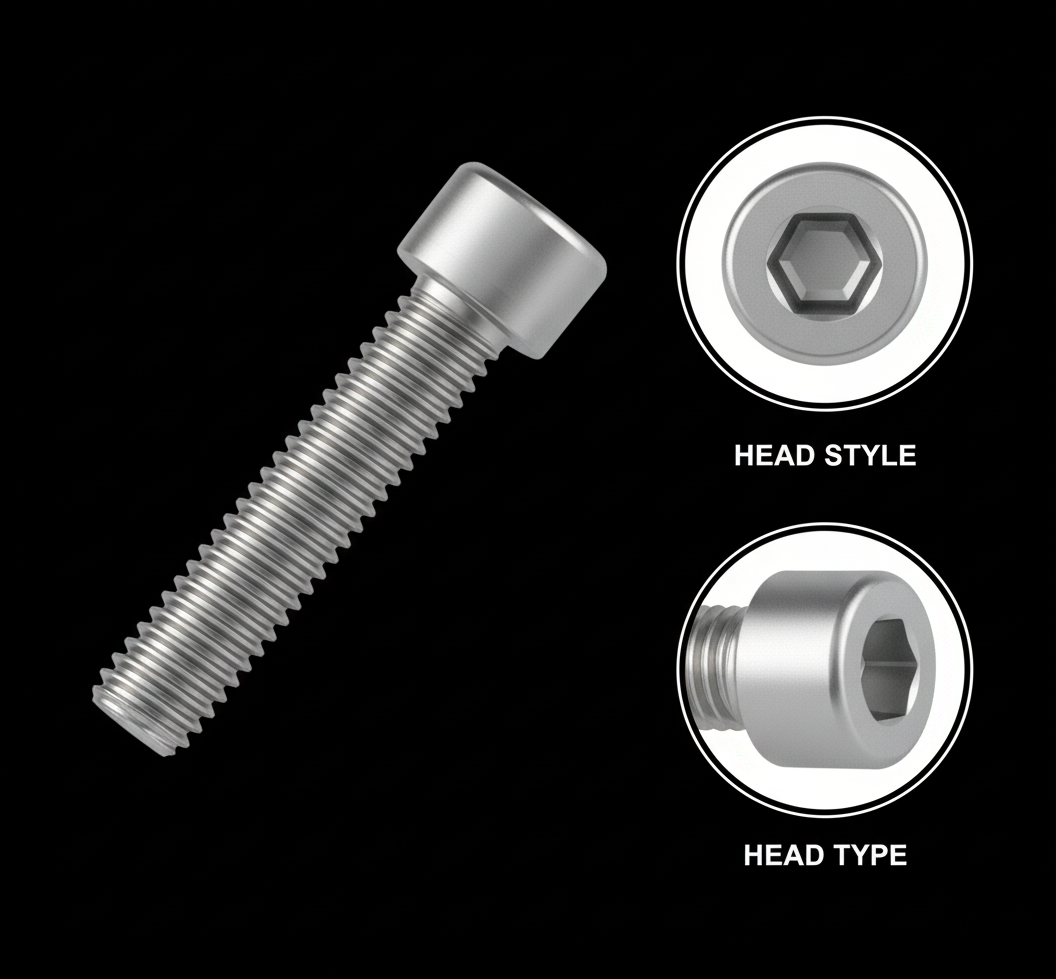

Allen screws, also known as socket head cap screws, represent the pinnacle of precision fastening technology. With their hexagonal socket drive and cylindrical head design, these screws deliver exceptional torque capacity, clean aesthetics, and reliable performance in demanding applications. This comprehensive guide explores every variant available at ScrewBazar—from standard SHCS to specialized GRUB and JCB screws.

1. Understanding Allen Screw Fundamentals

Allen screws are precision machine screws designed for applications requiring high clamping force and accurate torque control. The hexagonal socket (hex socket) in the head accepts Allen keys (hex keys), allowing significant torque transfer without the cam-out issues common with Phillips or slotted drives. The cylindrical head profile provides a strong, low-profile fastening solution ideal where space is limited. Manufactured to exacting tolerances following ISO 4762 (metric) and DIN 912 standards, Allen screws ensure consistent quality and interchangeability. Socket depth and dimensions are standardized, enabling reliable tool engagement and preventing rounded sockets. The cylindrical head distributes clamping force uniformly, making these screws ideal for high-stress applications in machinery, automotive, aerospace, and industrial equipment. Material grades include 8.8, 10.9, and 12.9 strength classes for carbon steel, with stainless steel SS304 and SS316 variants for corrosion resistance. Thread types include coarse pitch (standard) and fine pitch for precision applications requiring minimal vibration loosening. At ScrewBazar, we stock Allen screws from M1.6 (electronics) to M20 (heavy machinery) in lengths from 3mm to 200mm, ensuring the perfect fastener for every application.

Shop Allen Screws →

Shop Allen Screws →

2. SHCS Machine Screws - The Standard Bearer

SHCS (Socket Head Cap Screws) are the most widely used Allen screw type, featuring a tall cylindrical head with internal hex socket. The high head profile (typically equal to screw diameter) provides maximum socket depth for secure tool engagement and exceptional torque capacity. SHCS are engineered for applications requiring highest clamping force—the head design withstands immense tensile loads without failure. Common applications include CNC machine tool assembly (securing precision components), automotive engine components (cylinder heads, bearing caps), industrial machinery (gear boxes, pump housings), robotics (structural joints), and heavy equipment (construction machinery, mining equipment). Material selection is critical: Grade 8.8 for general industrial use (800 MPa tensile strength), Grade 10.9 for high-stress applications (1000 MPa tensile strength), Grade 12.9 for extreme-duty applications (1200 MPa tensile strength), Stainless Steel SS304 for outdoor/marine/food processing (corrosion resistance), and SS316 for chemical/pharmaceutical environments (superior corrosion resistance). Installation requires proper torque: M3=1.2 Nm, M4=2.4 Nm, M5=4.9 Nm, M6=8.4 Nm, M8=20.7 Nm, M10=41 Nm (Grade 8.8). Always use correctly sized Allen key—worn keys round socket and destroy screw head. Pair SHCS with appropriate washers for load distribution and lock nuts or thread locker for vibration resistance.

Browse SHCS Screws →

Browse SHCS Screws →

3. BHCS Machine Screws - Button Head for Low-Profile Aesthetics

BHCS (Button Head Cap Screws) feature a low-profile, rounded head with internal hex socket, providing aesthetic appeal combined with functional performance. The button head is approximately half the height of SHCS, making BHCS ideal where clearance is limited or protruding heads would be undesirable. Despite lower profile, BHCS maintain impressive torque capacity through optimized socket depth and head geometry. The rounded contour prevents snagging and reduces injury risk in applications where hands or materials contact fastener heads. BHCS are extensively used in furniture assembly (visible fastening with clean appearance), automotive interiors (dashboard, trim, seats where aesthetics matter), sports equipment (bicycles, motorcycles, fitness machines), consumer electronics (laptop hinges, monitor stands), and architectural applications (handrails, decorative panels). The smooth, rounded head also facilitates easier installation in recessed areas where access is restricted. Available in carbon steel grades 8.8 and 10.9 for strength, stainless steel SS304 for outdoor exposure, and black oxide finish for premium aesthetic in high-end products. Torque capacity is approximately 70-80% of equivalent SHCS due to reduced head height, but still exceeds Phillips or slotted alternatives. Installation tip: ensure socket is clean and dry before engagement—contamination reduces grip and can round socket. BHCS pair excellently with plain washers to increase bearing surface on softer materials.

Shop BHCS Screws →

Shop BHCS Screws →

4. CSK Machine Screws - Countersunk for Flush Mounting

Allen CSK (Countersunk) machine screws combine the flush-mounting advantages of countersunk heads with the superior torque control of hex socket drives. The conical head (typically 90° included angle) sits completely below the material surface when installed in properly countersunk holes, creating smooth, streamlined finishes without protruding fasteners. This makes CSK Allen screws essential where aerodynamics, aesthetics, or snag-prevention are critical. The hex socket provides reliable torque transfer even when head is recessed, unlike slotted countersunk screws which are difficult to drive when flush or below surface. CSK Allen screws are indispensable in aerospace (aluminum skin panels, fairings where drag reduction matters), automotive body panels (trunk lids, door skins requiring flush exterior), machinery guards and covers (safety panels where protruding fasteners create hazards), furniture (drawer fronts, cabinet doors for clean lines), and metal fabrication (decorative panels, architectural features). Installation requires careful countersinking—hole angle must match screw head angle (typically 90° or 82°) and depth must position head flush or slightly below surface. Countersink depth affects clamp load distribution; too deep reduces bearing surface. Materials include carbon steel with zinc plating (general use), stainless steel SS304 (outdoor/marine), and anodized aluminum-compatible coatings (prevent galvanic corrosion). CSK screws develop lower clamp loads than cylindrical head types due to angled bearing surface—increase length or diameter if maximum clamping force is required. Use countersunk washers when installing in soft materials to prevent pull-through.

Explore CSK Allen Screws →

Explore CSK Allen Screws →

5. Allen Flange Button Head - Integrated Washer Design

Allen flange button head screws feature an integrated flange (built-in washer) beneath the button head, combining the aesthetic appeal of BHCS with the load-distribution advantages of flanged fasteners. The flange increases bearing surface area by 2-3x compared to standard button head, preventing damage to soft materials and providing superior vibration resistance. This eliminates need for separate washers, reducing assembly time and part count in high-volume manufacturing. The flange also creates friction that resists loosening in vibration-prone applications. Flange button head screws are popular in automotive assembly (interior trim panels, seat mechanisms), appliances (control panels, door hinges), electronics enclosures (chassis mounting), machinery covers (guard panels), and anywhere thin sheet metal, plastic, or composite materials require secure fastening without pull-through risk. The rounded button head maintains low profile while flange distributes clamping load evenly. Materials include carbon steel zinc-plated for general use, stainless steel SS304 for corrosion resistance, and A2/A4 stainless grades for food-grade or medical applications. Installation torque should be monitored carefully—overtightening can embed flange into soft materials, while undertightening won't fully engage anti-vibration benefits. Common sizes range from M4 to M10 with lengths from 6mm to 40mm. The combination of button head aesthetics, hex socket drive, and integral flange makes these screws versatile problem-solvers for modern assembly challenges. Order from ScrewBazar with detailed technical specifications and bulk discounts for OEM quantities.

6. GRUB Screws (Set Screws) - Locking Without Protrusion

GRUB screws, also called set screws, are headless Allen screws designed to be installed completely below the surface, sitting flush or recessed within threaded holes. Unlike standard screws that clamp parts together, GRUB screws lock components onto shafts, prevent rotation, or act as adjustment stops—all without protruding above the assembly surface. The entire screw body is threaded (or partially threaded with smooth pilot section) and features hex socket at one end and various point styles at the other. Point styles include: Cup Point (most common, creates small indentation in shaft for secure grip), Flat Point (broad bearing surface, won't damage shaft), Cone Point (penetrates shaft for maximum grip in soft materials), Dog Point (extended pilot for precise location in machined grooves), and Oval Point (minimal shaft marking for hardened surfaces). GRUB screws are essential in collar and pulley mounting (securing components on rotating shafts), gear positioning (preventing axial or rotational movement), door hinge adjustment (threaded stops for precise alignment), machinery clamping (temporary shaft locks during maintenance), and precision location pins (repeatable component positioning). Materials include hardened alloy steel (Grade 14.9 for high holding force), stainless steel SS304 (corrosion resistance in marine/food applications), brass (non-sparking in hazardous environments), and nylon (non-marring for precision shafts). Installation requires proper torque and point selection—cup point for general locking, flat point where shaft damage is unacceptable, cone point for maximum grip. Always apply appropriate thread locker (Loctite 243 for removable, 271 for permanent) to prevent loosening under vibration. Popular sizes include M3, M4, M5, M6, M8 in lengths from 3mm to 50mm.

Shop GRUB Screws →

Shop GRUB Screws →

7. JCB Screws - Heavy-Duty Construction Fasteners

JCB screws are specialized Allen screws designed for heavy construction equipment, earthmoving machinery, and industrial vehicles. Named after their widespread use in JCB (construction equipment manufacturer) machinery, these screws are built to withstand extreme loads, vibration, shock, and harsh environmental conditions encountered in construction and mining operations. JCB screws typically feature extra-deep hex sockets for positive tool engagement even when caked with mud or debris, high-strength materials (often Grade 10.9 or 12.9), and specialized coatings for corrosion resistance in outdoor exposure. The design emphasizes reliability under cyclic loading, impact resistance, and resistance to vibration loosening—critical factors in heavy equipment where fastener failure can cause catastrophic damage or safety hazards. Applications include excavator arm and bucket mounting, loader bucket attachment points, hydraulic cylinder mounting, boom and stick connections, undercarriage components (track links, roller mounting), and engine/transmission mounting brackets. Materials are selected for both strength and toughness: high-grade alloy steel with protective coatings (zinc-flake, geomet, dacromet) to withstand salt, moisture, and temperature extremes. Thread-locking features may be incorporated (thread patches, prevailing torque, mechanical locking). Installation requires calibrated torque wrenches and strict adherence to manufacturer specifications—under-torquing allows movement and wear, over-torquing causes thread stripping or screw fracture. Regular inspection and retorquing are essential in heavy equipment maintenance schedules. JCB screws often come with certification documenting material grade, heat treatment, and traceability—critical for equipment manufacturers and operators maintaining quality standards. At ScrewBazar, we supply genuine-grade JCB screws meeting OEM specifications with full technical documentation and bulk pricing for fleet maintenance and equipment repair operations.

Expert Allen Screw Selection and Supply

From standard SHCS for maximum strength to specialized GRUB screws for locking applications, ScrewBazar provides India's most comprehensive Allen screw range. Our technical team assists with grade selection, torque specifications, and material recommendations for your specific application. Contact us for detailed technical data sheets, installation guidelines, bulk pricing, and same-day dispatch across India.